ROTOCONE VACUUM DRYER

The RotoCone Vacuum Dryer is an advanced drying equipment designed to handle heat-sensitive materials in industries such as pharmaceuticals, chemicals, and food processing. It uses a rotating cone-shaped drum under vacuum conditions to facilitate efficient drying while minimizing heat exposure. The vacuum environment lowers the boiling point of solvents, allowing for a gentle and uniform drying process. The dryer is constructed with high-quality stainless steel, ensuring durability and easy cleaning. Its unique design enhances heat transfer and reduces processing time. The RotoCone Vacuum Dryer is equipped with a sealing system that prevents contamination and ensures product quality. It is highly efficient, offering reduced energy consumption compared to traditional drying methods. The system provides a controlled atmosphere, ensuring precise moisture content. Its user-friendly controls allow for easy operation and monitoring. The equipment complies with GMP standards, making it suitable for high-quality production processes.

- Designed for heat-sensitive materials, ensuring gentle drying.

- Operates under vacuum conditions to reduce boiling points and preserve quality.

- Rotating cone design enhances heat transfer and reduces drying time.

- Made of stainless steel for durability and easy maintenance.

- Provides a controlled environment for precise moisture control.

- Energy-efficient, reducing energy consumption compared to conventional dryers.

- Prevents contamination with an effective sealing system.

Related products

COLLOID MILL

- Reduces particle size and creates homogeneous mixtures.

- Works through high-speed shearing, grinding, and mixing.

- Ideal for liquid or semi-liquid materials.

- Ensures consistency in emulsions or suspensions.

- Compact and easy to operate with minimal maintenance.

- Stainless steel construction for durability and hygiene.

- Energy-efficient design reduces operational costs.

- Suitable for a wide range of viscosities and industries.

DISTILLATION COLUMNS

- Used for separating mixtures by boiling point differences.

- Available in types like packed and tray columns.

- Made with durable, corrosion-resistant materials.

- Suitable for a range of pressures and temperatures.

- Provide precise control over temperature and pressure.

- Designed for high efficiency and energy optimization.

- Customizable to meet specific industrial requirements.

- Ensures consistent performance and reliability.

- Widely used in chemical, petrochemical, and pharmaceutical industries.

HEAT EXCHANGERS

- Facilitates efficient heat transfer between fluids.

- Prevents mixing of the fluids being heated or cooled.

- Available in various designs like shell and tube, plate, and air-cooled.

- Made from corrosion-resistant materials for durability.

- Supports process stability by controlling temperature changes.

- Compact and adaptable for different industrial needs.

- Capable of handling high pressure and temperature conditions.

- Easy to integrate into existing systems with a modular design.

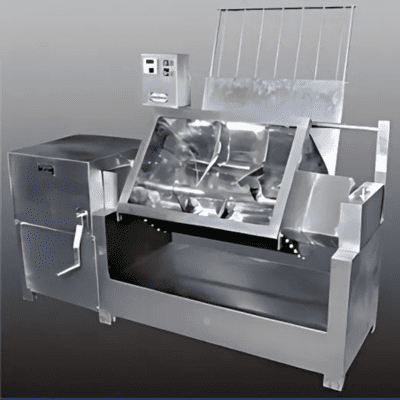

MASS MIXER

- Ideal for mixing powders, granules, and wet materials.

- Robust stainless-steel construction for durability and hygiene.

- Paddle-type blade ensures uniform and efficient mixing.

- Tilting mechanism for easy discharge and reduced effort.

- Energy-efficient and simple to operate.

- Designed to comply with GMP standards for safety.

- Compact design saves space in industrial setups.

Reviews

There are no reviews yet.