Ointment Manufacturing Plant in Mumbai – India

Welcome To Muniji Pharmatech

Muniji Pharmatech is incepted in the year 2012, a partnership firm based on manufacturing of pharma- ceutical, food, chemical, cosmetic machineries and equipment. And also provide spares and mainte- nance of all kind of equipment relat- ed to our machineries. We are en- gaged in manufacturing of widest range of machineries for pharma- ceutical, cosmetic, food, dairy and chemical industries. All machines are customized that are uniquely designed according to cus- tomer specification of their shape, size, materials and capacity. The Muniji Pharmatech are experts in manufacturing top qualityof phar- maceutical machinery in stainless steel (304, 316) as per contact parts to products.

Welcome To Muniji Pharmatech

Muniji Pharmatech is incepted in the year 2012, a partnership firm based on manufacturing of pharma- ceutical, food, chemical, cosmetic machineries and equipment. And also provide spares and mainte- nance of all kind of equipment relat- ed to our machineries. We are en- gaged in manufacturing of widest range of machineries for pharma- ceutical, cosmetic, food, dairy and chemical industries. All machines are customized that are uniquely designed according to cus- tomer specification of their shape, size, materials and capacity. The Muniji Pharmatech are experts in manufacturing top qualityof phar- maceutical machineries in stainless steel (304, 316) as per contact parts to products. Ointment Manufacturing Plant in Mumbai – India

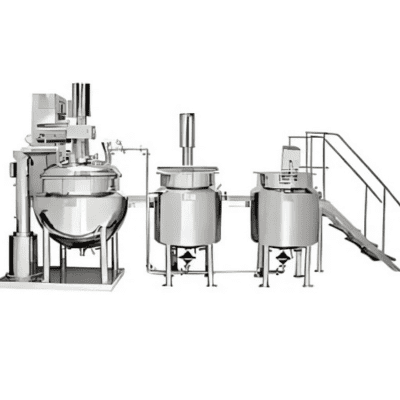

Ointment Cream Manufacturing Plant

Ointment/Cream Manufacturing Plants are ideal tools for the Pharmaceutical, Cosmetics & Consumer Care Industries for the production of Ointment, Cream, Lotions, Tooth Paste (Medicated, Herbals etc.) and other emulsions & homogenizations. It is specially designed to take care of two critical factors which directly affects the quality of the Ointment/Creams.

Liquid Oral Syrup Processing Plant

Liquid oral/Syrup Manufacturing Plant is an ideal tool for the Pharmaceutical, Drugs Industries for the production of Oral Liquids. Muniji Liquid Oral Processing plants are designed with the highest quality of fabrication standards using the best components & instruments and its fully optimized for delivering the best performance.

Fluid Bed Dryer

Fluid Bed Dryer (FBD) works on the principle of fluidization, a process in which hot gas or air is introduced into the spaces between solid particles. Upward forces on the particles increase as the air’s velocity increases causing them to equal the gravitational forces below.

OUR PRODUCTS!

AIR TRAY DRYER

- Versatile use: Ideal for drying raw materials, granules, and powders.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Uniform drying: Hot air evenly distributed through perforated trays.

- Energy efficient: Double-walled insulation minimizes heat loss.

- Temperature control: Adjustable settings for different materials.

- Batch operation: Accommodates multiple trays for increased productivity.

- Quality preservation: Gentle drying suitable for sensitive materials.

AUTO COATER

- Used for coating tablets, pills, and particles in pharmacetical and food industries.

- Ensures uniform coating with a controlled spray system.

- Features a perforated drum for even distribution of coating material.

- Advanced airflow and heating systems for faster drying.

- User-friendly controls for precise parameter adjustments.

- Supports multiple coating types, including film and enteric.

- Stainless steel construction ensures hygiene and durability.

- Compact design for space-saving and cost-effective production.

CO-MILL

- Versatile use: Ideal for size reduction, granulation, and de-lumping.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Precise output: Supports interchangeable screens for consistent particle size.

- Heat management: Operates with low heat to protect sensitive materials.

- Compact design: Easy to integrate into production lines.

- High throughput: Efficient processing for continuous production needs.

- Low noise and vibration: Ensures a safe and comfortable work environment.

- Easy maintenance: Simple to clean and maintain.

COLLOID MILL

- Reduces particle size and creates homogeneous mixtures.

- Works through high-speed shearing, grinding, and mixing.

- Ideal for liquid or semi-liquid materials.

- Ensures consistency in emulsions or suspensions.

- Compact and easy to operate with minimal maintenance.

- Stainless steel construction for durability and hygiene.

- Energy-efficient design reduces operational costs.

- Suitable for a wide range of viscosities and industries.

DISTILLATION COLUMNS

- Used for separating mixtures by boiling point differences.

- Available in types like packed and tray columns.

- Made with durable, corrosion-resistant materials.

- Suitable for a range of pressures and temperatures.

- Provide precise control over temperature and pressure.

- Designed for high efficiency and energy optimization.

- Customizable to meet specific industrial requirements.

- Ensures consistent performance and reliability.

- Widely used in chemical, petrochemical, and pharmaceutical industries.

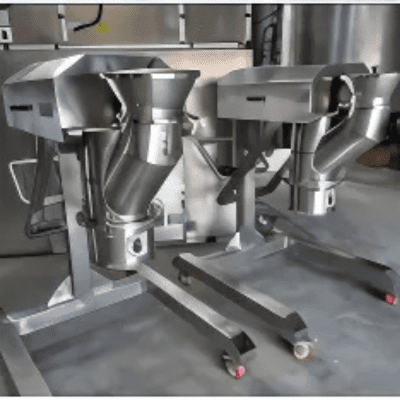

DOUBLE CONE BLENDER

- Pharmaceutical, food, cosmetic, chemical, and dairy industries.

- Machines are designed and built as per customer specifications, including shape, size, material, and capacity.

- Manufactured using premium stainless steel (304, 316) for durability, hygiene, and product safety.

- Includes mixers, blenders, granulators, dryers, reactors, filling machines, and more.

- Comprehensive after-sales service, including spare parts supply and equipment maintenance.

- Designed to meet strict industry standards for cleanliness and operational safety.

- Focused on maximizing productivity while minimizing operational costs.

FLUID BED DRYER

HEAT EXCHANGERS

- Facilitates efficient heat transfer between fluids.

- Prevents mixing of the fluids being heated or cooled.

- Available in various designs like shell and tube, plate, and air-cooled.

- Made from corrosion-resistant materials for durability.

- Supports process stability by controlling temperature changes.

- Compact and adaptable for different industrial needs.

- Capable of handling high pressure and temperature conditions.

- Easy to integrate into existing systems with a modular design.

LIQUID ORAL SYRUP PROCESSING PLANT

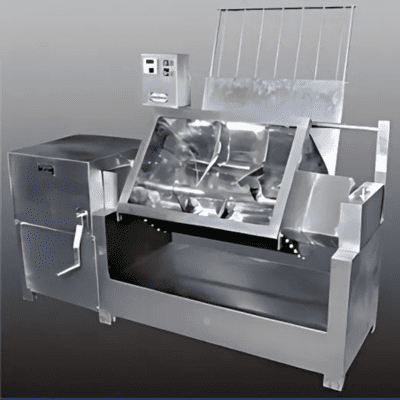

MASS MIXER

- Ideal for mixing powders, granules, and wet materials.

- Robust stainless-steel construction for durability and hygiene.

- Paddle-type blade ensures uniform and efficient mixing.

- Tilting mechanism for easy discharge and reduced effort.

- Energy-efficient and simple to operate.

- Designed to comply with GMP standards for safety.

- Compact design saves space in industrial setups.

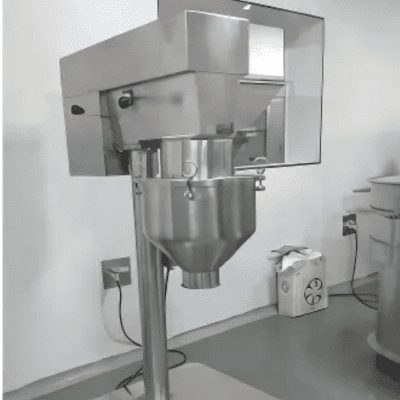

MULTI MILL

- Versatile use: Suitable for granulation, size reduction, and mixing across industries.

- Hygienic design: Made from stainless steel, ensuring durability and cleanliness.

- Efficient operation: High-speed rotor with customizable attachments for varied outputs.

- Heat management: Operates with low heat, protecting sensitive materials.

- Easy maintenance: Modular design allows for quick cleaning and part changes.

- Adjustable output: Multiple screen options for precise granulation consistency.

- Energy efficiency: Provides high throughput while conserving energy.

- Low noise and vibration: Ensures smooth and safe operation.

- Portable and compact: Easy to move and suitable for constrained spaces.

OCTAGONAL BLENDER

- Shape: The octagonal design ensures efficient tumbling and uniform mixing.

- Capacity: Suitable for large-scale production with high-volume handling.

- Gentle Mixing: Minimizes material degradation during the blending process.

- Material: Often constructed with stainless steel for durability and hygiene.

- Efficiency: Reduces dead spots, ensuring no material remains unmixed.

- Features: May include spray nozzles for liquid addition during blending.

- Maintenance: Easy to clean and maintain, saving time in production cycles.

Experience the Difference

Production

Scalability

High Quality

Production

Global Compititive

Costs

Maximize

Insights

Unparalleled Lead

Flexible Manufacturing

Maximize Transparancy & Visibility

Increase Manufacturing Realibility

Industry We Serve

-WHY CHOOSE US-

Quality Products

Every single unit of muniji is made from the AISI 316L, AISI 316, AISI 304 top grade SS mate- rial that gives 100% resistance against corrosion and excellent durability against extreme con- ditions which ensures a high level of sanitation throughout its life expectancy as well as every single design of the equipment strongly meets the cGMP stan- dards of quality and safety.

Expertise

Muniji Pharmatech specializes in manufacturing high-quality pharmaceutical, food, chemical, and cosmetic machinery. With over a decade of experience, we offer customized solutions tailored to specific customer requirements, including shape, size, materials, and capacity. Our machines are crafted from stainless steel (304, 316) for durability and product safety.

Customization

At Muniji Pharmatech, we prioritize innovation and customization to meet the unique needs of our clients. Each machinery is meticulously designed and tailored to the exact specifications of the customer, ensuring maximum efficiency and performance. Whether it’s for the pharmaceutical, cosmetic, food, dairy.

Ointment Manufacturing Plant in Mumbai – India