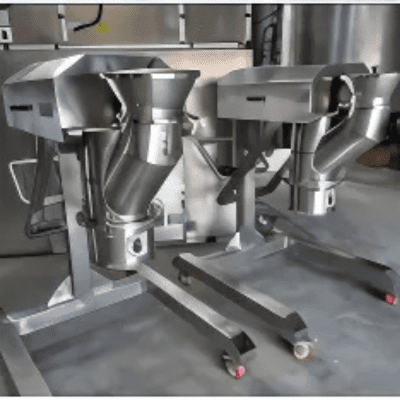

REACTORS

Reactors are essential equipment used in industries such as pharmaceuticals, chemicals, petrochemicals, and food processing for carrying out chemical reactions under controlled conditions. They are designed to handle a range of processes, including mixing, heating, cooling, and agitation, ensuring optimal reaction efficiency. Reactors are typically constructed from robust materials like stainless steel or glass-lined steel to resist corrosion and withstand high pressure and temperature. They come in various types, such as batch, continuous, and catalytic, to cater to different industrial needs. Equipped with advanced temperature and pressure control systems, reactors ensure precision and safety during operations. Agitators and baffles within the reactor enhance mixing and heat transfer, improving the overall process. Modern reactors may also include automation features for improved process control and efficiency. They are customizable in size and configuration to suit specific applications. Maintenance-friendly designs ensure long-term usability and cost-effectiveness.

- Used for chemical reactions under controlled conditions.

- Supports processes like mixing, heating, cooling, and agitation.

- Constructed from corrosion-resistant materials for durability.

- Types include batch, continuous, and catalytic reactors.

- Advanced control systems for precise temperature and pressure management.

- Agitators and baffles improve mixing and heat transfer efficiency.

- Customizable designs to meet specific industrial requirements.

Related products

AIR TRAY DRYER

- Versatile use: Ideal for drying raw materials, granules, and powders.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Uniform drying: Hot air evenly distributed through perforated trays.

- Energy efficient: Double-walled insulation minimizes heat loss.

- Temperature control: Adjustable settings for different materials.

- Batch operation: Accommodates multiple trays for increased productivity.

- Quality preservation: Gentle drying suitable for sensitive materials.

CO-MILL

- Versatile use: Ideal for size reduction, granulation, and de-lumping.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Precise output: Supports interchangeable screens for consistent particle size.

- Heat management: Operates with low heat to protect sensitive materials.

- Compact design: Easy to integrate into production lines.

- High throughput: Efficient processing for continuous production needs.

- Low noise and vibration: Ensures a safe and comfortable work environment.

- Easy maintenance: Simple to clean and maintain.

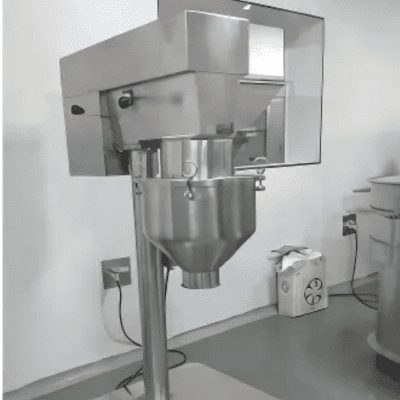

MULTI MILL

- Versatile use: Suitable for granulation, size reduction, and mixing across industries.

- Hygienic design: Made from stainless steel, ensuring durability and cleanliness.

- Efficient operation: High-speed rotor with customizable attachments for varied outputs.

- Heat management: Operates with low heat, protecting sensitive materials.

- Easy maintenance: Modular design allows for quick cleaning and part changes.

- Adjustable output: Multiple screen options for precise granulation consistency.

- Energy efficiency: Provides high throughput while conserving energy.

- Low noise and vibration: Ensures smooth and safe operation.

- Portable and compact: Easy to move and suitable for constrained spaces.

VACUUM TARY DRYER

- Drying method suitable for heat-sensitive materials.

- Operates in a low-pressure environment to lower drying temperatures.

- Uniform drying achieved through trays in a vacuum chamber.

- Precise temperature controls to prevent product degradation.

- Efficient moisture removal for faster processing times.

- Constructed with stainless steel for durability and hygiene.

- Easy to clean and maintain for seamless operations.

- Available in customizable sizes to suit industrial needs.

Reviews

There are no reviews yet.