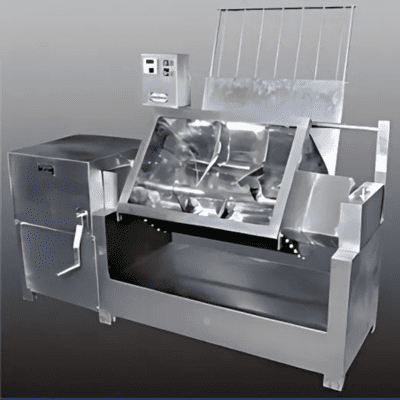

RAPID MIXER GARNULATOR

A Rapid Mixer Granulator is an advanced piece of equipment widely used in the pharmaceutical, chemical, and food industries for efficient mixing and granulation of powders and granules. It operates on the principle of high-speed blending and granulation, ensuring uniform particle size distribution. The equipment comprises a specially designed mixing bowl, an impeller, and a chopper that work together to mix ingredients thoroughly and break down clumps. It significantly reduces processing time while maintaining the desired granule consistency. The machine offers precise control over granule size by adjusting the speed and time of operation. Constructed from high-quality stainless steel, it ensures durability, hygiene, and resistance to corrosion. Rapid mixer granulators are compact, easy to clean, and adhere to GMP standards. They are ideal for batch production and can handle a wide range of materials, making them versatile for various applications.

- Used for efficient mixing and granulation in industries.

- Ensures uniform particle size distribution.

- Equipped with a mixing bowl, impeller, and chopper.

- Reduces processing time with high-speed operations.

- Allows precise control over granule size.

- Built with durable and hygienic stainless steel.

- Compact design and easy-to-clean structure.

- Complies with GMP standards for quality assurance.

Related products

AUTO COATER

- Used for coating tablets, pills, and particles in pharmacetical and food industries.

- Ensures uniform coating with a controlled spray system.

- Features a perforated drum for even distribution of coating material.

- Advanced airflow and heating systems for faster drying.

- User-friendly controls for precise parameter adjustments.

- Supports multiple coating types, including film and enteric.

- Stainless steel construction ensures hygiene and durability.

- Compact design for space-saving and cost-effective production.

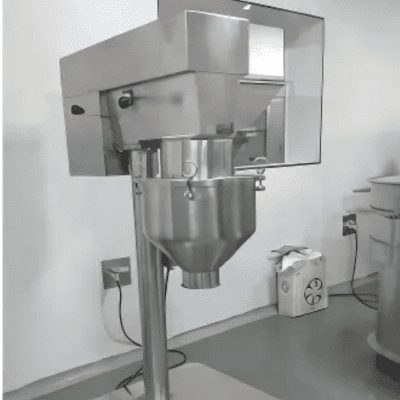

CO-MILL

- Versatile use: Ideal for size reduction, granulation, and de-lumping.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Precise output: Supports interchangeable screens for consistent particle size.

- Heat management: Operates with low heat to protect sensitive materials.

- Compact design: Easy to integrate into production lines.

- High throughput: Efficient processing for continuous production needs.

- Low noise and vibration: Ensures a safe and comfortable work environment.

- Easy maintenance: Simple to clean and maintain.

FLUID BED DRYER

MULTI MILL

- Versatile use: Suitable for granulation, size reduction, and mixing across industries.

- Hygienic design: Made from stainless steel, ensuring durability and cleanliness.

- Efficient operation: High-speed rotor with customizable attachments for varied outputs.

- Heat management: Operates with low heat, protecting sensitive materials.

- Easy maintenance: Modular design allows for quick cleaning and part changes.

- Adjustable output: Multiple screen options for precise granulation consistency.

- Energy efficiency: Provides high throughput while conserving energy.

- Low noise and vibration: Ensures smooth and safe operation.

- Portable and compact: Easy to move and suitable for constrained spaces.

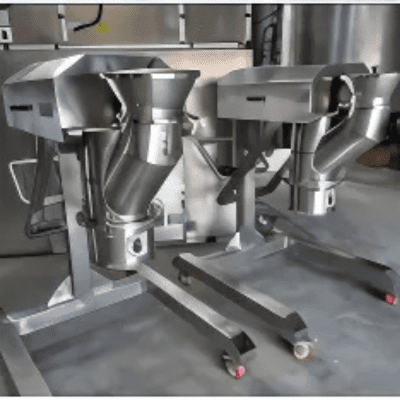

STARCH PASTE KETTLE

- Designed for preparing starch paste used in various industries.

- Hemispherical shape ensures uniform heating and mixing.

- Efficient agitator prevents lump formation during cooking.

- Operates with steam or electric heating for precise temperature control.

- Made of stainless steel for durability and hygiene compliance.

- Features a tilting mechanism for easy discharge.

- Compact design suitable for small and large-scale use.

- Easy to clean and maintain for consistent performance.

TABLET COATING PAN

- Provides uniform coating for tablets and capsules.

- Stainless steel rotating pan ensures even distribution.

- Equipped with a spraying system for precise coating application.

- Hot air circulation enables quick and efficient drying.

- Maintains a controlled environment for accurate results.

- Robust design for durability and hygiene compliance.

- Available in different capacities for varied production needs.

- Easy to clean and maintain, reducing operational downtime.

Reviews

There are no reviews yet.