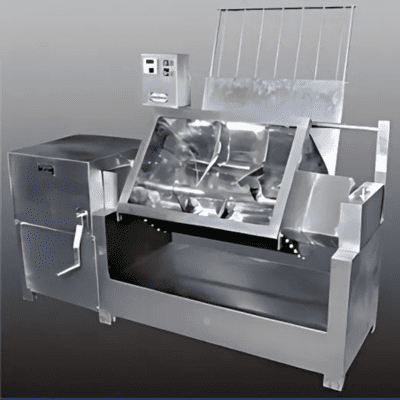

MASS MIXER

A Mass Mixer is a versatile machine primarily used in the pharmaceutical, food, and chemical industries for mixing large quantities of materials uniformly. It is ideal for blending powders, granules, and wet materials effectively, ensuring consistency in the final product. The mixer consists of a robust stainless-steel drum with a paddle-type blade that rotates to achieve a homogenous mix. Its design ensures minimal material wastage and easy discharge. Equipped with a tilting mechanism, it simplifies the removal of mixed material and reduces manual effort. The machine is energy-efficient, easy to operate, and designed for long-lasting performance. It also complies with GMP standards, making it safe for pharmaceutical use. Additionally, its compact design saves floor space while delivering optimal functionality. Suitable for a variety of applications, it is a reliable choice for high-capacity mixing requirements.

- Ideal for mixing powders, granules, and wet materials.

- Robust stainless-steel construction for durability and hygiene.

- Paddle-type blade ensures uniform and efficient mixing.

- Tilting mechanism for easy discharge and reduced effort.

- Energy-efficient and simple to operate.

- Designed to comply with GMP standards for safety.

- Compact design saves space in industrial setups.

Related products

COLLOID MILL

- Reduces particle size and creates homogeneous mixtures.

- Works through high-speed shearing, grinding, and mixing.

- Ideal for liquid or semi-liquid materials.

- Ensures consistency in emulsions or suspensions.

- Compact and easy to operate with minimal maintenance.

- Stainless steel construction for durability and hygiene.

- Energy-efficient design reduces operational costs.

- Suitable for a wide range of viscosities and industries.

DISTILLATION COLUMNS

- Used for separating mixtures by boiling point differences.

- Available in types like packed and tray columns.

- Made with durable, corrosion-resistant materials.

- Suitable for a range of pressures and temperatures.

- Provide precise control over temperature and pressure.

- Designed for high efficiency and energy optimization.

- Customizable to meet specific industrial requirements.

- Ensures consistent performance and reliability.

- Widely used in chemical, petrochemical, and pharmaceutical industries.

HEAT EXCHANGERS

- Facilitates efficient heat transfer between fluids.

- Prevents mixing of the fluids being heated or cooled.

- Available in various designs like shell and tube, plate, and air-cooled.

- Made from corrosion-resistant materials for durability.

- Supports process stability by controlling temperature changes.

- Compact and adaptable for different industrial needs.

- Capable of handling high pressure and temperature conditions.

- Easy to integrate into existing systems with a modular design.

ROTOCONE VACUUM DRYER

- Designed for heat-sensitive materials, ensuring gentle drying.

- Operates under vacuum conditions to reduce boiling points and preserve quality.

- Rotating cone design enhances heat transfer and reduces drying time.

- Made of stainless steel for durability and easy maintenance.

- Provides a controlled environment for precise moisture control.

- Energy-efficient, reducing energy consumption compared to conventional dryers.

- Prevents contamination with an effective sealing system.

Reviews

There are no reviews yet.