Showing all 7 results

AUTO COATER

An Auto Coater is an advanced machine designed for the efficient coating of tablets, pills, or other small particles in the pharmaceutical and food industries. This equipment uses a controlled spray system to evenly coat the products with a fine layer of coating material, such as film or sugar, enhancing their appearance, taste, and shelf-life. The machine's perforated drum ensures uniform distribution of the coating, while its advanced airflow and heating systems speed up the drying process without compromising product quality. Auto coaters are equipped with user-friendly controls, allowing precise regulation of parameters like spray rate, temperature, and drum speed. These machines are highly versatile, capable of handling various coating processes like film, sugar, or enteric coating. They are also constructed with stainless steel for hygiene and durability. Compact and efficient, auto coaters save time and reduce operational costs, making them essential for large-scale production.

- Used for coating tablets, pills, and particles in pharmacetical and food industries.

- Ensures uniform coating with a controlled spray system.

- Features a perforated drum for even distribution of coating material.

- Advanced airflow and heating systems for faster drying.

- User-friendly controls for precise parameter adjustments.

- Supports multiple coating types, including film and enteric.

- Stainless steel construction ensures hygiene and durability.

- Compact design for space-saving and cost-effective production.

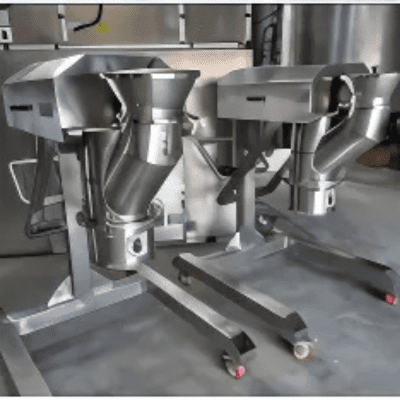

CO-MILL

The Co-Mill is a highly efficient milling machine designed for size reduction, granulation, and de-lumping processes in industries such as pharmaceuticals, food, chemicals, and cosmetics. It operates on the principle of centrifugal force, using a rotating impeller with a perforated screen to achieve consistent particle size. Constructed with stainless steel, it ensures hygiene and durability, making it suitable for cleanroom environments. The machine supports interchangeable screens, enabling precise control over particle size. Its compact and portable design allows for easy integration into production lines. The Co Mill is designed for low heat generation, preserving the quality of heat-sensitive materials. It provides high throughput and operates with minimal noise and vibration, ensuring a safe working environment. The equipment is GMP compliant, reflecting its adherence to quality and safety standards. Easy to clean and maintain, the Co Mill is a reliable solution for efficient material processing.

- Versatile use: Ideal for size reduction, granulation, and de-lumping.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Precise output: Supports interchangeable screens for consistent particle size.

- Heat management: Operates with low heat to protect sensitive materials.

- Compact design: Easy to integrate into production lines.

- High throughput: Efficient processing for continuous production needs.

- Low noise and vibration: Ensures a safe and comfortable work environment.

- Easy maintenance: Simple to clean and maintain.

FLUID BED DRYER

Fluid Bed Dryer (FBD) works on the principle of fluidization, a process in which hot gas or air is introduced into the spaces between solid particles. Upward forces on the particles increase as the air's velocity increases causing them to equal the gravitational forces below.

• Capacity - 5 to 500 Kgs.

•MOC-SS/SS304/SS316/SS316L.

•Drying bowl is easy to load and unload in system due to castor wheels,

• Inflatable silicon tube for bag sealing & product container sealing.

• Online Sampling Device.

-Steam Valve controlled through Panel with solenoid valve to control the steam temperature.

.PLC with HMI screen and FLP Motor & FLP Panel (optional).

Air Handling Unit with Hepa Filtration.

• Pneumatically operated Inlet & outlet Dampers.

• VFD for Blower

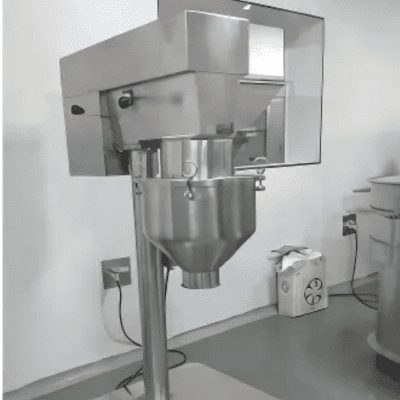

MULTI MILL

The Multi Mill is a versatile and efficient equipment widely used in industries like pharmaceuticals, chemicals, food, and cosmetics for size reduction, granulation, and mixing of materials. It features a compact, portable design with a stainless steel construction that ensures durability and hygiene. The mill operates on the principle of centrifugal force, utilizing a high-speed rotor with different attachments to suit various processing needs. Its modular design allows for easy assembly and disassembly, facilitating quick cleaning and maintenance. The machine supports multiple screen sizes to achieve precise output consistency. It operates with low heat generation, preserving the integrity of heat-sensitive materials. The Multi Mill is energy-efficient and provides high throughput, making it an essential tool for continuous production.

- Versatile use: Suitable for granulation, size reduction, and mixing across industries.

- Hygienic design: Made from stainless steel, ensuring durability and cleanliness.

- Efficient operation: High-speed rotor with customizable attachments for varied outputs.

- Heat management: Operates with low heat, protecting sensitive materials.

- Easy maintenance: Modular design allows for quick cleaning and part changes.

- Adjustable output: Multiple screen options for precise granulation consistency.

- Energy efficiency: Provides high throughput while conserving energy.

- Low noise and vibration: Ensures smooth and safe operation.

- Portable and compact: Easy to move and suitable for constrained spaces.

RAPID MIXER GARNULATOR

A Rapid Mixer Granulator is an advanced piece of equipment widely used in the pharmaceutical, chemical, and food industries for efficient mixing and granulation of powders and granules. It operates on the principle of high-speed blending and granulation, ensuring uniform particle size distribution. The equipment comprises a specially designed mixing bowl, an impeller, and a chopper that work together to mix ingredients thoroughly and break down clumps. It significantly reduces processing time while maintaining the desired granule consistency. The machine offers precise control over granule size by adjusting the speed and time of operation. Constructed from high-quality stainless steel, it ensures durability, hygiene, and resistance to corrosion. Rapid mixer granulators are compact, easy to clean, and adhere to GMP standards. They are ideal for batch production and can handle a wide range of materials, making them versatile for various applications.

- Used for efficient mixing and granulation in industries.

- Ensures uniform particle size distribution.

- Equipped with a mixing bowl, impeller, and chopper.

- Reduces processing time with high-speed operations.

- Allows precise control over granule size.

- Built with durable and hygienic stainless steel.

- Compact design and easy-to-clean structure.

- Complies with GMP standards for quality assurance.

STARCH PASTE KETTLE

A Starch Paste Kettle is a specialized piece of equipment used for preparing starch paste, a critical component in various industries such as pharmaceuticals, food, and textiles. This kettle features a hemispherical design for even heat distribution, ensuring uniform mixing and consistent paste quality. It is equipped with an efficient agitator mechanism to prevent lump formation during the cooking process. The kettle operates with steam or electric heating, providing precise temperature control for optimal paste preparation. Constructed from stainless steel, it ensures high durability, corrosion resistance, and compliance with hygiene standards. The tilting mechanism allows for easy discharge of the paste, reducing manual effort and improving operational efficiency. Its compact design makes it suitable for small and large-scale operations. The kettle is also designed for easy cleaning and maintenance, making it a reliable choice for industries requiring consistent starch paste production.

- Designed for preparing starch paste used in various industries.

- Hemispherical shape ensures uniform heating and mixing.

- Efficient agitator prevents lump formation during cooking.

- Operates with steam or electric heating for precise temperature control.

- Made of stainless steel for durability and hygiene compliance.

- Features a tilting mechanism for easy discharge.

- Compact design suitable for small and large-scale use.

- Easy to clean and maintain for consistent performance.

TABLET COATING PAN

A Tablet Coating Pan is a vital piece of equipment used in the pharmaceutical industry to apply a uniform coating to tablets, capsules, or other products. It features a rotating stainless steel pan where the tablets are placed, ensuring even application of coating materials such as sugar, polymers, or films. The pan is integrated with a spraying system for precise and consistent coating. Hot air is circulated to dry the coating quickly, enhancing production efficiency. The device supports a controlled environment, allowing manufacturers to achieve desired coating thickness and texture. Its robust construction ensures durability and hygiene standards are maintained. The equipment is available in various capacities, catering to small-scale to large-scale production requirements. Its user-friendly design allows easy cleaning and maintenance, ensuring minimal downtime. Tablet coating pans are versatile, making them suitable for a variety of formulations and coatings.

- Provides uniform coating for tablets and capsules.

- Stainless steel rotating pan ensures even distribution.

- Equipped with a spraying system for precise coating application.

- Hot air circulation enables quick and efficient drying.

- Maintains a controlled environment for accurate results.

- Robust design for durability and hygiene compliance.

- Available in different capacities for varied production needs.

- Easy to clean and maintain, reducing operational downtime.