Showing all 4 results

DOUBLE CONE BLENDER

The Double Cone Blender is a versatile and efficient machine used for uniform mixing and blending of dry powders and granules in industries like pharmaceuticals, food, cosmetics, and chemicals. Its unique double-cone design ensures gentle yet thorough mixing, minimizing material degradation. Made from high-grade stainless steel (304 or 316), it is hygienic, durable, and easy to clean. Customizable in size and capacity, the blender is equipped with safety features and smooth operation mechanisms, making it an ideal choice for precision blending tasks in various industrial applications.

- Pharmaceutical, food, cosmetic, chemical, and dairy industries.

- Machines are designed and built as per customer specifications, including shape, size, material, and capacity.

- Manufactured using premium stainless steel (304, 316) for durability, hygiene, and product safety.

- Includes mixers, blenders, granulators, dryers, reactors, filling machines, and more.

- Comprehensive after-sales service, including spare parts supply and equipment maintenance.

- Designed to meet strict industry standards for cleanliness and operational safety.

- Focused on maximizing productivity while minimizing operational costs.

OCTAGONAL BLENDER

An octagonal blender is a versatile machine commonly used in factories, especially in industries like pharmaceuticals, chemicals, and food processing. Its unique octagonal shape ensures efficient and uniform mixing of granular or powdered materials. This design promotes a gentle yet thorough blending process, reducing the risk of material degradation. The blender typically consists of a rotating drum, a robust motor, and sometimes additional features like spray nozzles for liquid mixing. It is ideal for large-scale production due to its high capacity and reliable performance. The octagonal shape allows materials to tumble effectively, ensuring homogeneity. Its construction is often stainless steel for durability and hygiene. These machines are easy to operate, clean, and maintain. Their design minimizes dead spots, ensuring no material remains unmixed. They are crucial for maintaining consistency in industrial production processes.

- Shape: The octagonal design ensures efficient tumbling and uniform mixing.

- Capacity: Suitable for large-scale production with high-volume handling.

- Gentle Mixing: Minimizes material degradation during the blending process.

- Material: Often constructed with stainless steel for durability and hygiene.

- Efficiency: Reduces dead spots, ensuring no material remains unmixed.

- Features: May include spray nozzles for liquid addition during blending.

- Maintenance: Easy to clean and maintain, saving time in production cycles.

RIBBON BLENDER

A ribbon blender is a common industrial machine used for mixing powders, granules, and other dry materials. It consists of a horizontal U-shaped trough and a set of helical ribbons mounted on a rotating shaft. These ribbons, which include both outer and inner layers, move in opposite directions to ensure uniform mixing. Ribbon blenders are widely used in industries like food processing, pharmaceuticals, chemicals, and cosmetics. They are suitable for blending fine powders, granules, and materials with minor liquid content. The blender offers efficient mixing with minimal energy consumption and is designed for easy loading and unloading of materials. Its stainless steel construction ensures durability and hygiene. Ribbon blenders are often customizable with additional features such as heating, cooling, or spray systems for added functionality.

- Purpose: Used for mixing dry powders, granules, and low-viscosity materials in industries like pharmaceuticals, food, and chemicals.

- Design: Features a U-shaped horizontal trough and a helical ribbon agitator.

- Mixing Action: Inner and outer ribbons rotate in opposite directions, ensuring uniform mixing.

- Capacity: Suitable for bulk mixing with high efficiency.

- Material: Commonly made of stainless steel for hygiene and durability.

- Features: Can include options like heating, cooling, or liquid spray systems.

- Applications: Used in industries requiring consistent and homogenous blends.

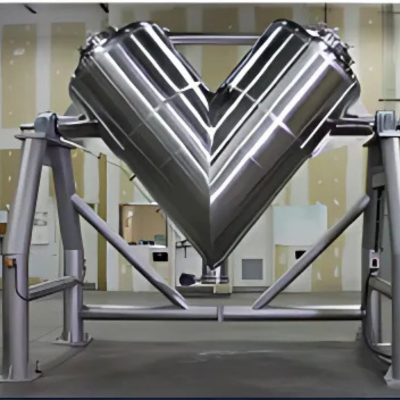

V BLENDER

A V blender is a widely used industrial mixing machine, particularly effective for blending dry powders and granular materials. It has a V-shaped design made up of two inclined cylinders joined at an angle, ensuring efficient and uniform mixing. The tumbling action within the V-shaped chamber achieves a thorough blend without degrading the material. V blenders are commonly used in pharmaceuticals, chemicals, and food industries due to their gentle mixing capabilities. They are often constructed with stainless steel to maintain hygiene and durability. The machine operates with low power consumption and minimal heat generation, preserving material properties. It is easy to clean and maintain, making it ideal for high-quality production processes. V blenders are suitable for materials that need precise and consistent mixing without requiring high shear forces.

- Purpose: Used for mixing dry powders and granular materials in industries like pharmaceuticals, food, and chemicals.

- Design: Features a V-shaped chamber formed by two inclined cylinders.

- Mixing Action: Achieves uniform blending through a gentle tumbling process.

- Material: Often made of stainless steel for hygiene and durability.

- Efficiency: Provides consistent mixing with low power consumption.

- Applications: Ideal for materials requiring precise, low-shear blending.

- Heat Generation: Minimal, preserving the properties of sensitive materials.

- Maintenance: Easy to clean and maintain, ensuring efficient operations.