Showing all 5 results

AIR TRAY DRYER

The Air Tray Dryer is an efficient drying machine used in industries such as pharmaceuticals, chemicals, food processing, and cosmetics for removing moisture from raw materials, granules, or powders. It operates by circulating hot air, which is evenly distributed through perforated trays to ensure uniform drying. The dryer is constructed with stainless steel, making it durable and easy to clean. Its double-walled insulated design minimizes heat loss, ensuring energy efficiency and consistent performance. The drying process is controlled with adjustable temperature settings, catering to various materials and drying requirements. The Air Tray Dryer is designed for batch operations and can accommodate multiple trays, enhancing productivity. It ensures gentle drying, preserving the quality and properties of sensitive materials. The machine operates quietly and complies with GMP standards, making it suitable for cleanroom environments. Its compact design and robust performance make it an essential tool for industrial drying processes.

- Versatile use: Ideal for drying raw materials, granules, and powders.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Uniform drying: Hot air evenly distributed through perforated trays.

- Energy efficient: Double-walled insulation minimizes heat loss.

- Temperature control: Adjustable settings for different materials.

- Batch operation: Accommodates multiple trays for increased productivity.

- Quality preservation: Gentle drying suitable for sensitive materials.

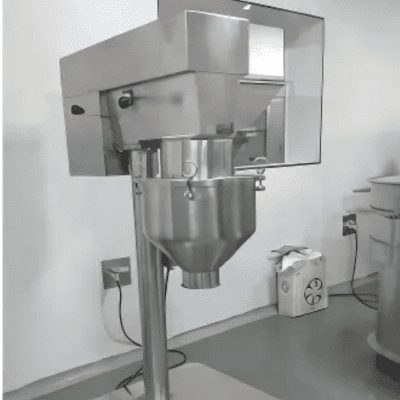

CO-MILL

The Co-Mill is a highly efficient milling machine designed for size reduction, granulation, and de-lumping processes in industries such as pharmaceuticals, food, chemicals, and cosmetics. It operates on the principle of centrifugal force, using a rotating impeller with a perforated screen to achieve consistent particle size. Constructed with stainless steel, it ensures hygiene and durability, making it suitable for cleanroom environments. The machine supports interchangeable screens, enabling precise control over particle size. Its compact and portable design allows for easy integration into production lines. The Co Mill is designed for low heat generation, preserving the quality of heat-sensitive materials. It provides high throughput and operates with minimal noise and vibration, ensuring a safe working environment. The equipment is GMP compliant, reflecting its adherence to quality and safety standards. Easy to clean and maintain, the Co Mill is a reliable solution for efficient material processing.

- Versatile use: Ideal for size reduction, granulation, and de-lumping.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Precise output: Supports interchangeable screens for consistent particle size.

- Heat management: Operates with low heat to protect sensitive materials.

- Compact design: Easy to integrate into production lines.

- High throughput: Efficient processing for continuous production needs.

- Low noise and vibration: Ensures a safe and comfortable work environment.

- Easy maintenance: Simple to clean and maintain.

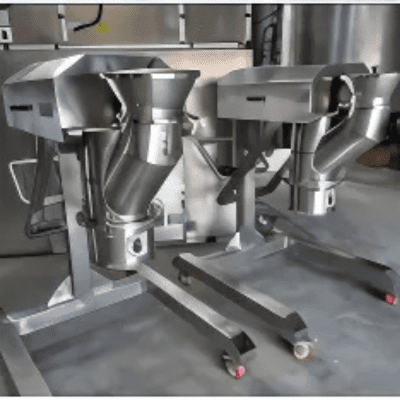

MULTI MILL

The Multi Mill is a versatile and efficient equipment widely used in industries like pharmaceuticals, chemicals, food, and cosmetics for size reduction, granulation, and mixing of materials. It features a compact, portable design with a stainless steel construction that ensures durability and hygiene. The mill operates on the principle of centrifugal force, utilizing a high-speed rotor with different attachments to suit various processing needs. Its modular design allows for easy assembly and disassembly, facilitating quick cleaning and maintenance. The machine supports multiple screen sizes to achieve precise output consistency. It operates with low heat generation, preserving the integrity of heat-sensitive materials. The Multi Mill is energy-efficient and provides high throughput, making it an essential tool for continuous production.

- Versatile use: Suitable for granulation, size reduction, and mixing across industries.

- Hygienic design: Made from stainless steel, ensuring durability and cleanliness.

- Efficient operation: High-speed rotor with customizable attachments for varied outputs.

- Heat management: Operates with low heat, protecting sensitive materials.

- Easy maintenance: Modular design allows for quick cleaning and part changes.

- Adjustable output: Multiple screen options for precise granulation consistency.

- Energy efficiency: Provides high throughput while conserving energy.

- Low noise and vibration: Ensures smooth and safe operation.

- Portable and compact: Easy to move and suitable for constrained spaces.

REACTORS

Reactors are essential equipment used in industries such as pharmaceuticals, chemicals, petrochemicals, and food processing for carrying out chemical reactions under controlled conditions. They are designed to handle a range of processes, including mixing, heating, cooling, and agitation, ensuring optimal reaction efficiency. Reactors are typically constructed from robust materials like stainless steel or glass-lined steel to resist corrosion and withstand high pressure and temperature. They come in various types, such as batch, continuous, and catalytic, to cater to different industrial needs. Equipped with advanced temperature and pressure control systems, reactors ensure precision and safety during operations. Agitators and baffles within the reactor enhance mixing and heat transfer, improving the overall process. Modern reactors may also include automation features for improved process control and efficiency. They are customizable in size and configuration to suit specific applications. Maintenance-friendly designs ensure long-term usability and cost-effectiveness.

- Used for chemical reactions under controlled conditions.

- Supports processes like mixing, heating, cooling, and agitation.

- Constructed from corrosion-resistant materials for durability.

- Types include batch, continuous, and catalytic reactors.

- Advanced control systems for precise temperature and pressure management.

- Agitators and baffles improve mixing and heat transfer efficiency.

- Customizable designs to meet specific industrial requirements.

VACUUM TARY DRYER

A Vacuum Tray Dryer is a specialized piece of equipment designed for drying heat-sensitive materials by creating a low-pressure environment that facilitates drying at lower temperatures. This is particularly useful for pharmaceutical, chemical, and food industries where product integrity is critical. The dryer consists of multiple trays placed within a vacuum chamber, ensuring uniform drying by conduction. With its ability to maintain precise temperature controls, it minimizes the risk of thermal degradation. The vacuum system also removes moisture efficiently, making the process quicker and more energy-efficient. Its robust design ensures reliability, while stainless steel construction offers corrosion resistance. The device is easy to clean and maintain, ensuring high levels of hygiene. Additionally, it operates with minimal noise, making it suitable for controlled environments. Versatile and adaptable, vacuum tray dryers are available in various sizes to meet different production needs.

- Drying method suitable for heat-sensitive materials.

- Operates in a low-pressure environment to lower drying temperatures.

- Uniform drying achieved through trays in a vacuum chamber.

- Precise temperature controls to prevent product degradation.

- Efficient moisture removal for faster processing times.

- Constructed with stainless steel for durability and hygiene.

- Easy to clean and maintain for seamless operations.

- Available in customizable sizes to suit industrial needs.