Table of Contents

ToggleOUR PRODUTCS

AIR TRAY DRYER

The Air Tray Dryer is an efficient drying machine used in industries such as pharmaceuticals, chemicals, food processing, and cosmetics for removing moisture from raw materials, granules, or powders. It operates by circulating hot air, which is evenly distributed through perforated trays to ensure uniform drying. The dryer is constructed with stainless steel, making it durable and easy to clean. Its double-walled insulated design minimizes heat loss, ensuring energy efficiency and consistent performance. The drying process is controlled with adjustable temperature settings, catering to various materials and drying requirements. The Air Tray Dryer is designed for batch operations and can accommodate multiple trays, enhancing productivity. It ensures gentle drying, preserving the quality and properties of sensitive materials. The machine operates quietly and complies with GMP standards, making it suitable for cleanroom environments. Its compact design and robust performance make it an essential tool for industrial drying processes.

- Versatile use: Ideal for drying raw materials, granules, and powders.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Uniform drying: Hot air evenly distributed through perforated trays.

- Energy efficient: Double-walled insulation minimizes heat loss.

- Temperature control: Adjustable settings for different materials.

- Batch operation: Accommodates multiple trays for increased productivity.

- Quality preservation: Gentle drying suitable for sensitive materials.

AUTO COATER

An Auto Coater is an advanced machine designed for the efficient coating of tablets, pills, or other small particles in the pharmaceutical and food industries. This equipment uses a controlled spray system to evenly coat the products with a fine layer of coating material, such as film or sugar, enhancing their appearance, taste, and shelf-life. The machine's perforated drum ensures uniform distribution of the coating, while its advanced airflow and heating systems speed up the drying process without compromising product quality. Auto coaters are equipped with user-friendly controls, allowing precise regulation of parameters like spray rate, temperature, and drum speed. These machines are highly versatile, capable of handling various coating processes like film, sugar, or enteric coating. They are also constructed with stainless steel for hygiene and durability. Compact and efficient, auto coaters save time and reduce operational costs, making them essential for large-scale production.

- Used for coating tablets, pills, and particles in pharmacetical and food industries.

- Ensures uniform coating with a controlled spray system.

- Features a perforated drum for even distribution of coating material.

- Advanced airflow and heating systems for faster drying.

- User-friendly controls for precise parameter adjustments.

- Supports multiple coating types, including film and enteric.

- Stainless steel construction ensures hygiene and durability.

- Compact design for space-saving and cost-effective production.

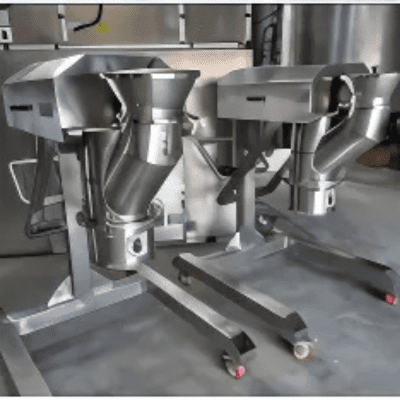

CO-MILL

The Co-Mill is a highly efficient milling machine designed for size reduction, granulation, and de-lumping processes in industries such as pharmaceuticals, food, chemicals, and cosmetics. It operates on the principle of centrifugal force, using a rotating impeller with a perforated screen to achieve consistent particle size. Constructed with stainless steel, it ensures hygiene and durability, making it suitable for cleanroom environments. The machine supports interchangeable screens, enabling precise control over particle size. Its compact and portable design allows for easy integration into production lines. The Co Mill is designed for low heat generation, preserving the quality of heat-sensitive materials. It provides high throughput and operates with minimal noise and vibration, ensuring a safe working environment. The equipment is GMP compliant, reflecting its adherence to quality and safety standards. Easy to clean and maintain, the Co Mill is a reliable solution for efficient material processing.

- Versatile use: Ideal for size reduction, granulation, and de-lumping.

- Hygienic construction: Made from stainless steel for durability and cleanliness.

- Precise output: Supports interchangeable screens for consistent particle size.

- Heat management: Operates with low heat to protect sensitive materials.

- Compact design: Easy to integrate into production lines.

- High throughput: Efficient processing for continuous production needs.

- Low noise and vibration: Ensures a safe and comfortable work environment.

- Easy maintenance: Simple to clean and maintain.

COLLOID MILL

A colloid mill is an advanced processing machine used for reducing particle size and creating homogeneous mixtures in industries like pharmaceuticals, food, cosmetics, and chemicals. It works by applying high-speed shearing, grinding, and mixing to liquid or semi-liquid materials, producing fine emulsions or suspensions. The mill consists of a rotor and stator that operate at high speeds, generating intense forces to break down particles. It is ideal for processing viscous substances and ensures consistency in product texture. The machine is compact, easy to operate, and requires minimal maintenance, making it a reliable choice for continuous operations. Its robust construction, typically in stainless steel, ensures durability and resistance to corrosion. The colloid mill is also designed for energy efficiency, reducing operational costs. Its ability to handle a wide range of viscosities makes it versatile for diverse industrial applications.

- Reduces particle size and creates homogeneous mixtures.

- Works through high-speed shearing, grinding, and mixing.

- Ideal for liquid or semi-liquid materials.

- Ensures consistency in emulsions or suspensions.

- Compact and easy to operate with minimal maintenance.

- Stainless steel construction for durability and hygiene.

- Energy-efficient design reduces operational costs.

- Suitable for a wide range of viscosities and industries.

DISTILLATION COLUMNS

Distillation columns are essential equipment used in chemical, petrochemical, and pharmaceutical industries for separating mixtures based on differences in their boiling points. They are designed to perform the process of distillation, where components are vaporized and condensed to achieve high-purity outputs. These columns are available in different types, such as packed columns and tray columns, depending on the specific separation requirements. Constructed using durable materials like stainless steel, they ensure long-term performance and resistance to corrosion. Distillation columns can handle a wide range of pressures and temperatures, making them suitable for various applications. They are equipped with advanced features for precise control of temperature and pressure, optimizing the separation process.

- Used for separating mixtures by boiling point differences.

- Available in types like packed and tray columns.

- Made with durable, corrosion-resistant materials.

- Suitable for a range of pressures and temperatures.

- Provide precise control over temperature and pressure.

- Designed for high efficiency and energy optimization.

- Customizable to meet specific industrial requirements.

- Ensures consistent performance and reliability.

- Widely used in chemical, petrochemical, and pharmaceutical industries.

DOUBLE CONE BLENDER

The Double Cone Blender is a versatile and efficient machine used for uniform mixing and blending of dry powders and granules in industries like pharmaceuticals, food, cosmetics, and chemicals. Its unique double-cone design ensures gentle yet thorough mixing, minimizing material degradation. Made from high-grade stainless steel (304 or 316), it is hygienic, durable, and easy to clean. Customizable in size and capacity, the blender is equipped with safety features and smooth operation mechanisms, making it an ideal choice for precision blending tasks in various industrial applications.

- Pharmaceutical, food, cosmetic, chemical, and dairy industries.

- Machines are designed and built as per customer specifications, including shape, size, material, and capacity.

- Manufactured using premium stainless steel (304, 316) for durability, hygiene, and product safety.

- Includes mixers, blenders, granulators, dryers, reactors, filling machines, and more.

- Comprehensive after-sales service, including spare parts supply and equipment maintenance.

- Designed to meet strict industry standards for cleanliness and operational safety.

- Focused on maximizing productivity while minimizing operational costs.

FLUID BED DRYER

Fluid Bed Dryer (FBD) works on the principle of fluidization, a process in which hot gas or air is introduced into the spaces between solid particles. Upward forces on the particles increase as the air's velocity increases causing them to equal the gravitational forces below.

• Capacity - 5 to 500 Kgs.

•MOC-SS/SS304/SS316/SS316L.

•Drying bowl is easy to load and unload in system due to castor wheels,

• Inflatable silicon tube for bag sealing & product container sealing.

• Online Sampling Device.

-Steam Valve controlled through Panel with solenoid valve to control the steam temperature.

.PLC with HMI screen and FLP Motor & FLP Panel (optional).

Air Handling Unit with Hepa Filtration.

• Pneumatically operated Inlet & outlet Dampers.

• VFD for Blower

HEAT EXCHANGERS

A Heat Exchanger is a vital industrial device designed to transfer heat between two or more fluids without mixing them. Commonly used in industries such as chemical processing, HVAC, and power generation, it enhances energy efficiency by recycling heat. Heat exchangers come in various designs, including shell and tube, plate, and air-cooled types, catering to different applications. They are built from durable materials like stainless steel or copper, ensuring long-term reliability and resistance to corrosion. By facilitating controlled temperature changes, they help maintain process stability and product quality. Compact and versatile, heat exchangers can handle high pressure and temperature conditions. Their modular design allows for easy integration into existing systems. With minimal maintenance requirements, they offer cost-effective and sustainable operation. These devices play a key role in optimizing energy consumption across diverse industries.

- Facilitates efficient heat transfer between fluids.

- Prevents mixing of the fluids being heated or cooled.

- Available in various designs like shell and tube, plate, and air-cooled.

- Made from corrosion-resistant materials for durability.

- Supports process stability by controlling temperature changes.

- Compact and adaptable for different industrial needs.

- Capable of handling high pressure and temperature conditions.

- Easy to integrate into existing systems with a modular design.

LIQUID ORAL SYRUP PROCESSING PLANT

Liquid oral/Syrup Manufacturing Plant is an ideal tool for the Pharmaceutical, Drugs Industries for the production of Oral Liquids. Muniji Liquid Oral Processing plants are designed with the highest quality of fabrication standards using the best components & instruments and its fully optimized for delivering the best performance with reduced operating cost.

• Capacity - 5 to 5000 Litres.

• MOC-SS 304/SS 316/ SS 316L.

• Total Liquid Mfg. Plant Consists of Syrup Mfg. Vessel, Sugar Melting Vessel, Storage Vessel, Pumps, Inline Homogenizer, Basket Filter, Sparkler Filter, Working Platform,

Interconnecting Pipeline and Control Panel.

All propeller agitations are from bottom.

Inline homogenizer can be provided as per requirement.

PLC based, with touch screen HMI and FLP Panel (optional).

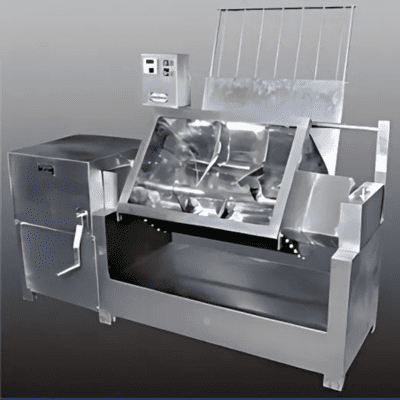

MASS MIXER

A Mass Mixer is a versatile machine primarily used in the pharmaceutical, food, and chemical industries for mixing large quantities of materials uniformly. It is ideal for blending powders, granules, and wet materials effectively, ensuring consistency in the final product. The mixer consists of a robust stainless-steel drum with a paddle-type blade that rotates to achieve a homogenous mix. Its design ensures minimal material wastage and easy discharge. Equipped with a tilting mechanism, it simplifies the removal of mixed material and reduces manual effort. The machine is energy-efficient, easy to operate, and designed for long-lasting performance. It also complies with GMP standards, making it safe for pharmaceutical use. Additionally, its compact design saves floor space while delivering optimal functionality. Suitable for a variety of applications, it is a reliable choice for high-capacity mixing requirements.

- Ideal for mixing powders, granules, and wet materials.

- Robust stainless-steel construction for durability and hygiene.

- Paddle-type blade ensures uniform and efficient mixing.

- Tilting mechanism for easy discharge and reduced effort.

- Energy-efficient and simple to operate.

- Designed to comply with GMP standards for safety.

- Compact design saves space in industrial setups.

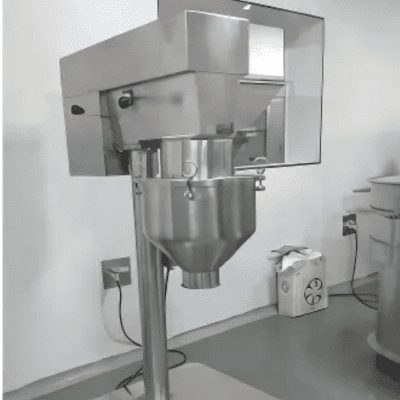

MULTI MILL

The Multi Mill is a versatile and efficient equipment widely used in industries like pharmaceuticals, chemicals, food, and cosmetics for size reduction, granulation, and mixing of materials. It features a compact, portable design with a stainless steel construction that ensures durability and hygiene. The mill operates on the principle of centrifugal force, utilizing a high-speed rotor with different attachments to suit various processing needs. Its modular design allows for easy assembly and disassembly, facilitating quick cleaning and maintenance. The machine supports multiple screen sizes to achieve precise output consistency. It operates with low heat generation, preserving the integrity of heat-sensitive materials. The Multi Mill is energy-efficient and provides high throughput, making it an essential tool for continuous production.

- Versatile use: Suitable for granulation, size reduction, and mixing across industries.

- Hygienic design: Made from stainless steel, ensuring durability and cleanliness.

- Efficient operation: High-speed rotor with customizable attachments for varied outputs.

- Heat management: Operates with low heat, protecting sensitive materials.

- Easy maintenance: Modular design allows for quick cleaning and part changes.

- Adjustable output: Multiple screen options for precise granulation consistency.

- Energy efficiency: Provides high throughput while conserving energy.

- Low noise and vibration: Ensures smooth and safe operation.

- Portable and compact: Easy to move and suitable for constrained spaces.

OCTAGONAL BLENDER

An octagonal blender is a versatile machine commonly used in factories, especially in industries like pharmaceuticals, chemicals, and food processing. Its unique octagonal shape ensures efficient and uniform mixing of granular or powdered materials. This design promotes a gentle yet thorough blending process, reducing the risk of material degradation. The blender typically consists of a rotating drum, a robust motor, and sometimes additional features like spray nozzles for liquid mixing. It is ideal for large-scale production due to its high capacity and reliable performance. The octagonal shape allows materials to tumble effectively, ensuring homogeneity. Its construction is often stainless steel for durability and hygiene. These machines are easy to operate, clean, and maintain. Their design minimizes dead spots, ensuring no material remains unmixed. They are crucial for maintaining consistency in industrial production processes.

- Shape: The octagonal design ensures efficient tumbling and uniform mixing.

- Capacity: Suitable for large-scale production with high-volume handling.

- Gentle Mixing: Minimizes material degradation during the blending process.

- Material: Often constructed with stainless steel for durability and hygiene.

- Efficiency: Reduces dead spots, ensuring no material remains unmixed.

- Features: May include spray nozzles for liquid addition during blending.

- Maintenance: Easy to clean and maintain, saving time in production cycles.

Load more products

Loading...